Description

The wavelength of the UV laser is about 355 nanometers; it is a short-wavelength laser. Short-wavelength lasers have higher photon energy, which can destroy the chemical bonds of materials directly with minimal thermal impact, achieving a high-precision, heat-free marking.

Another core advantage of UV laser marking is cold processing, which ensures a smooth and clear marking effect.

These advantages make the ultraviolet laser marker particularly suitable for applications with strict surface quality requirements. UV laser markers can process a wide range of materials, including plastics, glass, metals, ceramics, silicon wafers, and more.

3W 5W 10W Desktop Ultraviolet Laser Marker Components

3W 5W 10W Desktop Ultraviolet Laser Marker Dimensions

3W 5W 10W Desktop Ultraviolet Laser Marker Parameters

| MODEL | HTU-3 | HTU-5 | HTU-10 |

|---|---|---|---|

| Power | 3W | 5W | 10W |

| Laser source | JPT | JPT | JPT |

| Wavelength | 355nm | 355nm | 355nm |

| Frequency range | 20 kHz-150 kHz | 20 kHz-150 kHz | 20 kHz-150 kHz |

| Marking area | 110mm*110mm | 110mm*110mm | 110mm*110mm |

| Beam quality | M²≤1.2 | M²≤1.2 | M²≤1.2 |

| Beam diameter | 0.55±0.15mm | 0.55±0.15mm | 0.55±0.15mm |

| Supply voltage | DC 12V | DC 12V | DC 12V |

| Cooling method | Water-cooled | Water-cooled | Water-cooled |

| Galvo head | RC1001 | RC1001 | RC1001 |

| Dimensions | 890*775*1430mm | 890*775*1430mm | 890*775*1430mm |

3W 5W 10W Desktop Ultraviolet Laser Marker Features

Galvo Scanner

The RC1001 galvo scanner offers excellent linearity and high resolution, ensuring precise, repetitive positioning and high-speed scanning with minimal drift and strong anti-interference capabilities.

Industrial Water Chiller:

An industrial water chiller can ensure that the ultraviolet laser marker maintains a stable operating temperature for a long time and avoids machine failure due to overheating.

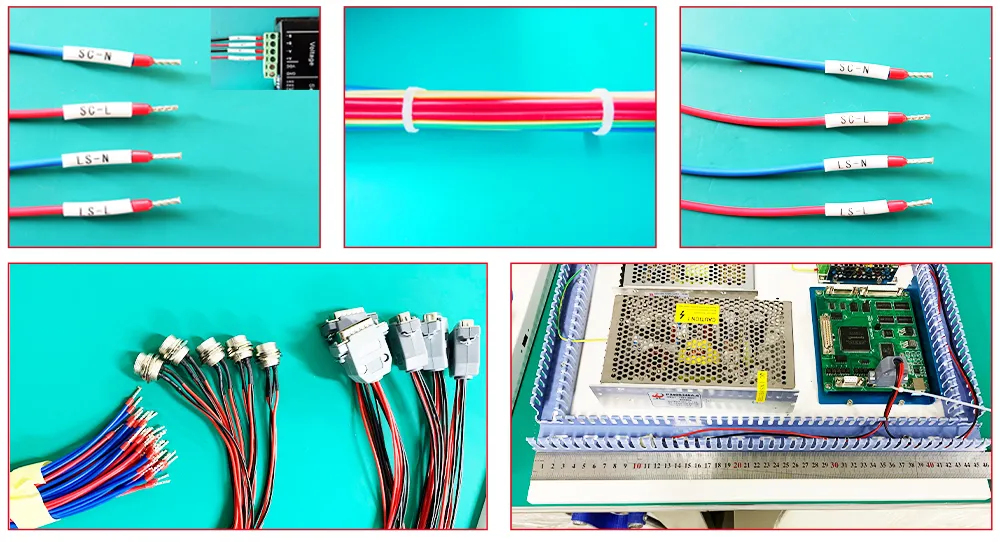

Well-organized Internal Wiring

PRINT INKS TECHNOLOGIES, ultraviolet laser marking machine features well-organized internal wiring that minimizes the risk of electrical shorts or malfunctions, ensuring smooth and reliable operation.

Organized wiring also simplifies maintenance tasks, making it easier for technicians to identify and address any issues that may arise.

3W 5W 10W Desktop Ultraviolet Laser Marking Samples

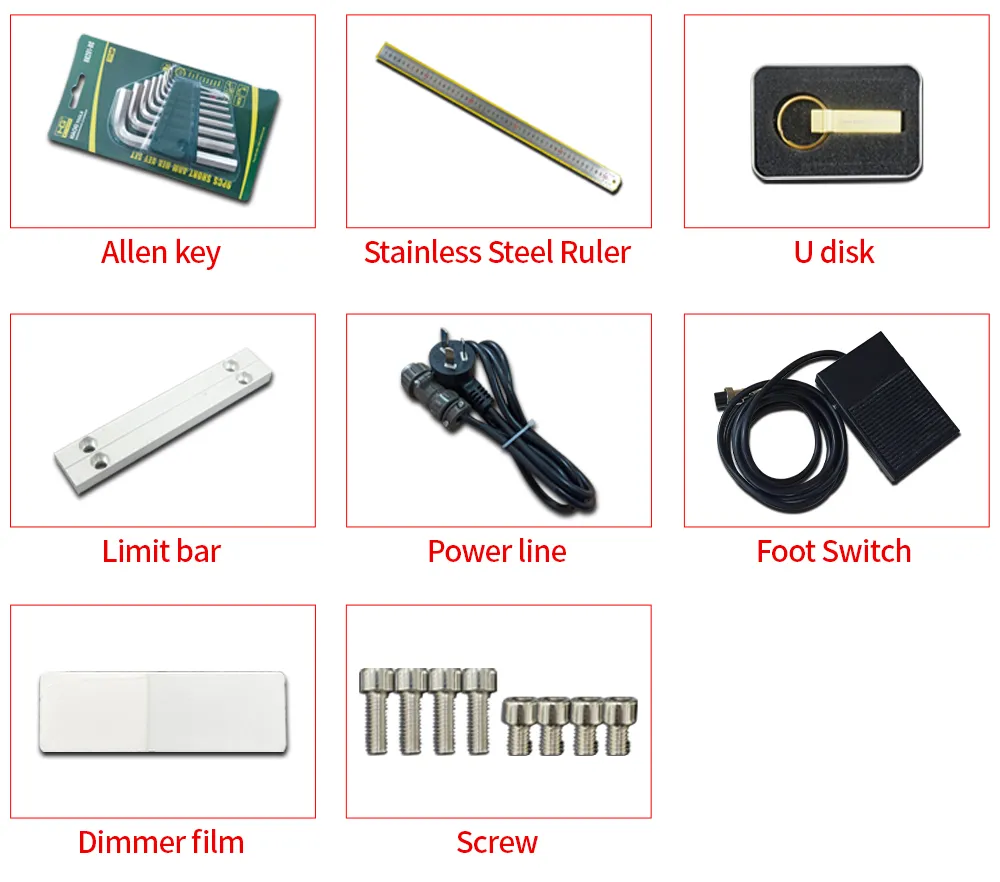

Included Accessories of UV Laser Marking Machine

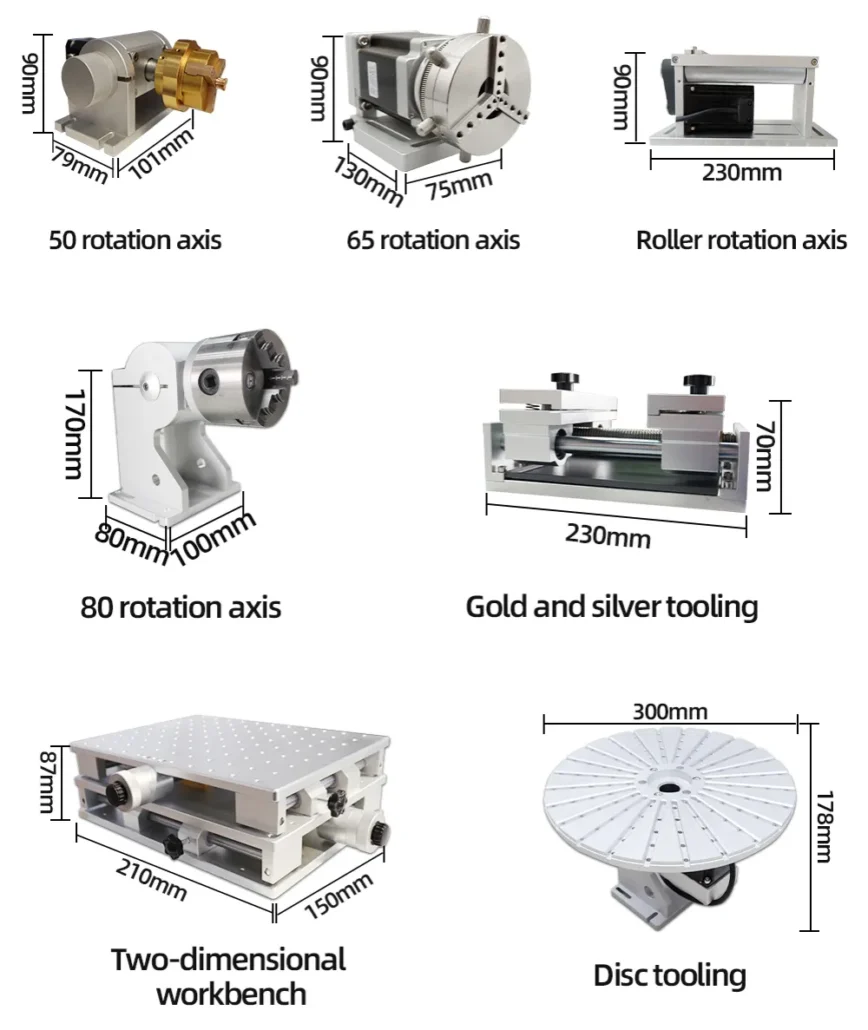

Accessory Selection of UV Laser Marking Machine